E. Coli in Cisterns: Risks, Testing, and Prevention

Cisterns are a reliable source of water for many households, cottages, farms, and off-grid properties. They provide essential storage, especially in areas without municipal water connections. But with any private water supply comes responsibility. One of the biggest risks cistern owners face is contamination, especially from E. coli.

E. coli in cisterns is more common than many people realize, and it can pose serious health risks if not addressed. This article explores how ecoli gets into cisterns, what it means for your health, how to test for it, and the best ways to prevent and manage contamination.

What is E. Coli?

E. coli, short for Escherichia coli, is a type of bacteria commonly found in the intestines of humans and animals. While many strains are harmless, some can cause illness when consumed in drinking water.

The presence of E. coli in a cistern is a red flag. It signals that the water has been contaminated with fecal matter, which may also contain other dangerous pathogens, viruses, or parasites. In other words, if your cistern tests positive for E. coli, it’s not just bacteria you need to worry about; it’s a broad indicator of unsafe water.

How Does E. Coli Get Into a Cistern?

Cistern contamination can happen in several ways:

1. Surface Runoff and Rainwater

If your cistern collects rainwater, contamination can occur when bird droppings or animal waste wash off the roof and into the tank. Even a small amount of droppings can introduce harmful bacteria.

2. Unsealed or Damaged Lids

A cracked or poorly sealed cistern lid invites trouble. Animals, insects, or debris can enter and introduce bacteria.

3. Water Delivery Trucks

If you rely on water deliveries, the truck hoses, tanks, or handling methods may not always be sanitary. One contaminated delivery is enough to seed your cistern with E. coli.

4. Nearby Septic Systems

Leaking or improperly maintained septic tanks can leach bacteria into the ground, eventually making their way into underground cisterns or water storage areas.

5. Poor Maintenance

Over time, sludge and biofilm can build up inside a cistern. This creates a perfect environment for bacteria to grow, especially if the tank is never cleaned or disinfected.

Health Risks of E. Coli in Cisterns

The health risks depend on the strain and the amount of exposure, but drinking or cooking with water contaminated by E. coli can lead to:

– Mild to severe diarrhea

– Stomach cramps

– Nausea and vomiting

– Fever

In severe cases, particularly with the strain E. coli O157:H7, infection can cause kidney damage and even be life-threatening—especially for young children, the elderly, or people with weakened immune systems.

Even if you don’t drink directly from your cistern, contaminated water can still be dangerous if used for brushing teeth, washing food, or accidentally swallowed during bathing.

How to Test for E. Coli in Your Cistern

The only reliable way to know if your cistern contains E. coli is to test it. Here’s how:

1. Collect a Water Sample

Use a sterilized bottle from a local health unit or certified lab. Take the sample from a tap that’s fed directly from the cistern, not from a filtered or treated line.

2. Submit to a Lab

Most health departments or private labs can test water samples for E. coli and total coliform bacteria. Results usually take 24–48 hours.

3. Interpret the Results

– No E. coli detected: Your water is currently safe from fecal contamination.

– E. coli detected: Immediate action is required. Do not drink the water until it is disinfected and retested.

– Total coliforms detected: While not as dangerous as E. coli, this indicates possible contamination pathways.

Routine testing is key. Many experts recommend testing cistern water at least 3–4 times per year, especially after maintenance, refilling, or heavy rains.

Free E. coli testing is available for all private wells in Ontario. Ontario.ca

How to Remove E. Coli from a Cistern

If a test comes back positive for E. coli, don’t panic; it can be dealt with. Here are the common steps:

1. Disinfection with Chlorine

The most common solution is to shock-chlorinate the cistern:

– Drain the tank if possible.

– Scrub and rinse the interior to remove sludge and debris.

– Refill with clean water.

– Add a chlorine solution (household bleach without additives works in emergencies) and circulate through the system.

– Allow the water to sit for several hours before flushing.

2. UV Filtration Systems

Installing a UV (ultraviolet) water purifier at the point of entry is a great long-term defense. UV systems kill bacteria like E. coli instantly without altering the taste of the water.

3. Ongoing Chlorination or Ozone

For households at high risk, a continuous disinfection system using chlorine or ozone can keep water safe.

4. Professional Cleaning

If your cistern has years of buildup, hiring a professional cleaning service ensures a thorough job. Or DIY cistern clean!

Preventing E. Coli in Cisterns

Prevention is always better than dealing with contamination after the fact. Here are best practices:

– Keep lids tightly sealed to prevent animal entry.

– Clean and disinfect your cistern annually.

– Inspect delivery hoses and request clean handling from water delivery companies.

– Install a first-flush diverter if using rainwater collection to redirect the initial dirty water off the roof.

– Test your water regularly to catch problems early.

– Add a point-of-use filter (such as reverse osmosis) for drinking water taps.

Common Questions About E. Coli in Cisterns

Can boiling water kill E. coli?

Yes. Boiling water for at least one minute kills E. coli and most other pathogens. This is a safe short-term solution until the cistern is disinfected.

Can I use bleach in my cistern all the time?

Small amounts of chlorine can help keep water safe, but too much can affect taste and smell. Regular testing is needed to keep levels balanced.

If my cistern tests positive once, will it always be contaminated?

Not necessarily. A one-time incident may be solved with cleaning and disinfection, but ongoing contamination suggests a larger problem with your system or environment.

Final Thoughts

E. coli in cisterns is not something to ignore. It signals a serious breach in water safety that can affect your health and the health of your family. The good news is that with regular testing, good maintenance practices, and effective disinfection strategies, you can keep your cistern water safe and reliable.

A cistern should be a dependable water source, not a hidden health hazard. By staying proactive, you can enjoy clean, safe water all year round.

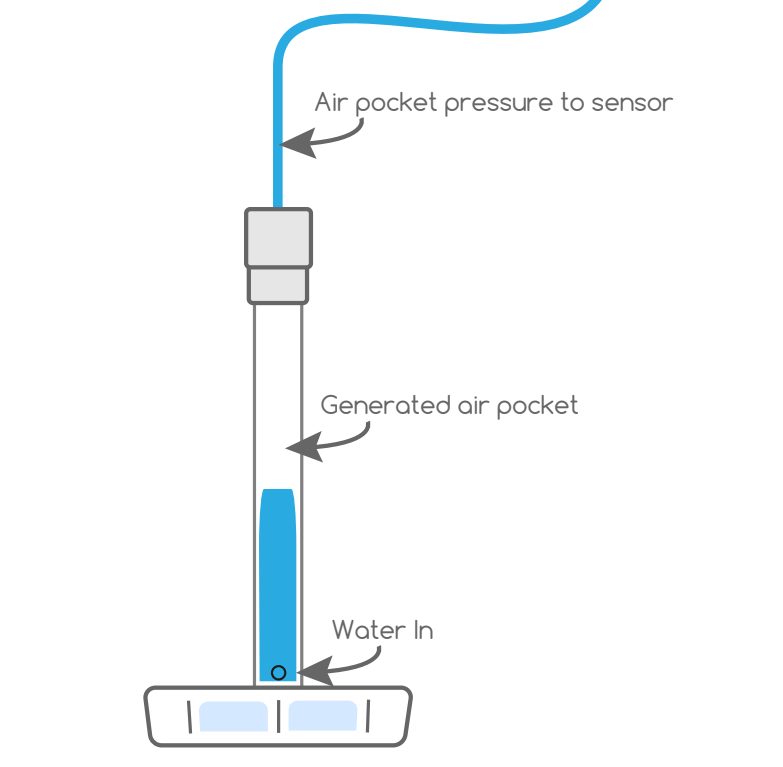

And if you want to learn how to monitor the liquid level in your cistern, please check out our Canadian-made PTLevels!