A Comparative Analysis of Pressure and Ultrasonic Sensors for Liquid Measurement

In the realm of liquid measurement, selecting the appropriate sensor is crucial for accurate and reliable results. We’ve put together a comparative analysis of pressure sensors and ultrasonic sensors used for liquid level monitoring and measurement. We hope the details on advantages and considerations are helpful as you plan your liquid level management. Among the myriad options available for liquid level measurement, pressure sensors and ultrasonic sensors stand out as two prominent contenders. This article aims to provide a comprehensive comparative analysis of these sensors, aiding readers in making an informed decision based on their specific application requirements. (Spoiler alert – we think pressure sensors, especially the PTlevel, win!)

Pressure Sensors

Benefits: Provides greater accuracy, cost-effective, can handle environmental extremes, low maintenance

Ultrasonic Sensors

Benefits: Non-contact with liquid, easy installation

Pressure Sensors (like the PTLevel):

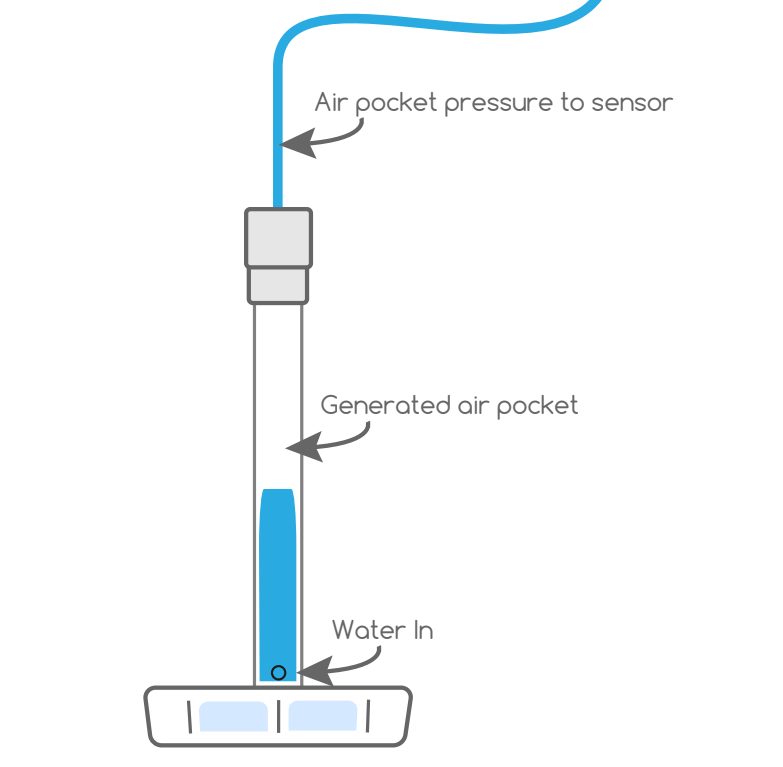

Pressure sensors operate on the principle of detecting the force exerted by a liquid on the sensor element. These sensors excel at measuring liquid depth, finding widespread application in tasks such as monitoring tank levels, overseeing industrial processes, tracking cistern levels, monitoring septic and holding tanks, and managing rainwater harvesting systems. Here are some key advantages and considerations when opting for pressure sensors:

Advantages of Pressure Sensors:

Accuracy and Precision: Pressure sensors exhibit remarkable accuracy and precision, particularly in applications where precise pressure measurements are essential. The PTLevel uses a 0kpa-100kpa sensor with an accuracy of 0.096kpa per bit, which is about 9.78mm of resolution.

Cost-Effectiveness: In many cases, pressure sensors are more cost-effective than their ultrasonic counterparts, making them a preferred choice for budget-conscious projects. And in every case we can find, the PTLevel beats the price of comparative systems with ultrasonic sensors!

Reliability in Specific Environments: Pressure sensors perform well in environments with challenging environmental conditions, such as high temperatures, freezing temperatures, or corrosive substances. Condensation, frost, and high humidity are not a concern for pressure sensors. (Yes, the PTLevel is also chemical resistant, weather resistant -40°C to 100°C temperature range, and built by Canadians for tough North American winters, making it ready to handle your most challenging environment!)

Low Maintenance: Pressure sensors require very little, or easy maintenance to operate accurately. For instance, pressure sensors sometimes have to have their “pressure” calibrated or reset. In the case of the PTLevel, we recommend seasonal maintenance to reset the air-pocket.

Considerations of Pressure Sensors:

Contact-Based Measurement: Pressure sensors require direct contact with the liquid. However, because the PTLevel is constructed with chemical-resistant materials and designed to withstand ice, snow, heat, and rain, you can confidently navigate any challenging liquid-level monitoring situation.

Installation Challenges: Depending on the application, installing pressure sensors may prove more complex than ultrasonic sensors, especially in scenarios where establishing physical contact with the liquid poses challenges. However, the PTLevel has eased this challenge by being designed for easy installation. Just connect the air pressure tubing to the pressure chamber and lower the pressure chamber into your liquid.

Ultrasonic Sensors:

Ultrasonic sensors utilize sound waves to measure the distance to the liquid surface. They are most known for their non-contact nature and are commonly employed in applications like wastewater monitoring. Here are some key points to consider:

Advantages of Ultrasonic Sensors:

Non-Contact Measurement: Ultrasonic sensors excel in scenarios where non-contact measurement is essential, preventing contamination of the liquid or potential damage to the sensor.

Easy Installation: These sensors are generally easier to install compared to pressure sensors, as they don’t require direct contact with the liquid.

Considerations of Ultrasonic Sensors:

Environmental Factors: Ultrasonic sensors may face difficulty in environments with high levels of dust, humidity, temperature fluctuations, or freezing temperatures. These factors can impact the accuracy of measurements. As soon as the sensor gets covered in dust, condensation, or frost, it can no longer provide accurate measurements.

Cost: While ultrasonic sensors offer unique advantages, they can be more expensive than pressure sensors, which may influence the decision-making process.

Maintenance: Dust, dirt, frost, and condensation or other debris can accumulate on the sensor, affecting the sensor’s performance. Regularly clean the sensor with a soft, lint-free cloth to ensure clear transmission and reception of ultrasonic signals.

Choosing the Right Sensor:

Ultimately, the choice between pressure and ultrasonic sensors depends on the specific requirements of the application. Factors such as accuracy, cost, installation complexity, and environmental conditions play a pivotal role in this decision-making process. Careful consideration of these factors will ensure that the selected sensor aligns perfectly with the goals of the liquid measurement system.

In conclusion, both pressure and ultrasonic sensors have their merits, and the optimal choice hinges on the unique demands of the application at hand. But we hope we’ve convinced you, the PTLevel is the perfect solution (with a 30-day money-back guarantee).

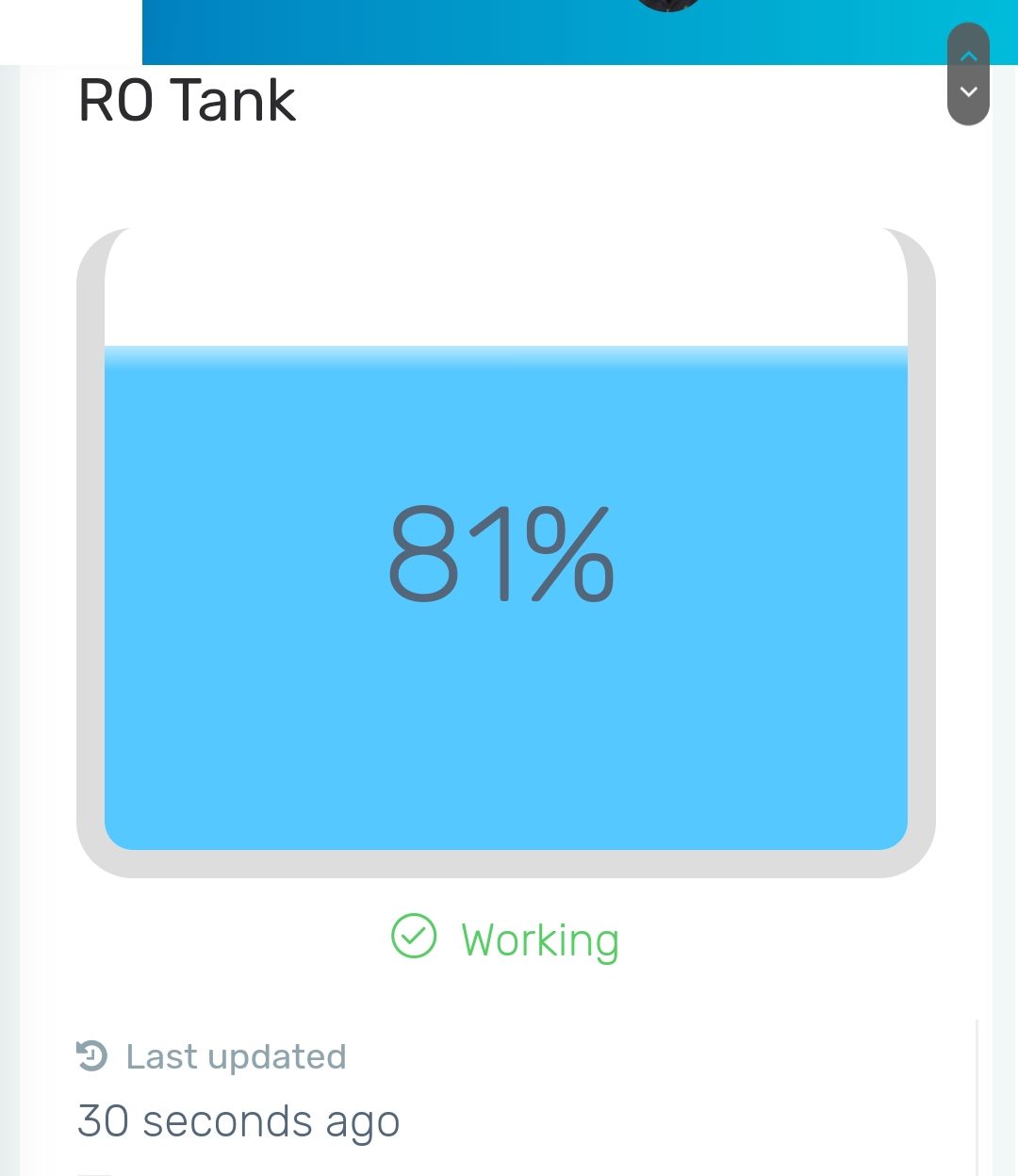

The PTLevel; Liquid Level Monitor with Pressure Sensor

Weather Resistant

Every PTLevel device is meticulously crafted to thrive in outdoor environments. Designed for -40°C to 85°C temperature range and handle snow, ice, or rain. And with using innovative Lora technology, 1 km or more can be achieved depending on the environment.

Accurate

Leveraging a state-of-the-art 0-100kPa pressure sensor and cutting-edge circuitry and software, the PTLevel ensures precise liquid level measurements. Enjoy peace of mind with its extended 2+ year battery life, receive timely alerts for low or high levels, and access a comprehensive liquid level history.

Cost Effective

Starting as low as $209.99 USD with no annual fees (for the Wired WiFi PTLevel) and $299.99 USD with no annual fees (for the Long Range Wireless PTLevel), it’s an affordable liquid measurement option! By avoiding equipment damage caused by water outages and staying informed to schedule water deliveries only when necessary, you’ll not only enhance efficiency but also realize substantial cost savings.